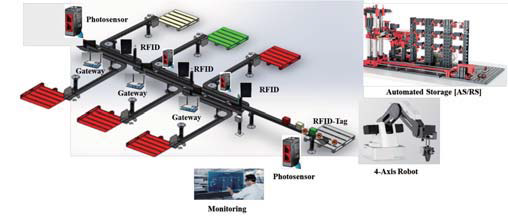

Features:

1. Sensor, RFID and SW are integrated management of production process monitoring and work records

2. Through the convergence of IoT, gateway, monitoring system, etc., the entire production process is itelligentized and optimized to suit the production process

3. Customized practice based on advanced manufacturing technologies such as IoT and process simulation techniques are available for all processes such a production by product process and defect management.

4. Conveyor belt transfer and inspection test practice

5. Automatic warehouse system practice possible

6. 4-axis robot x, y, z-axis movement

7. Practice of numerical data transfer command using digital switch

Functions:

1. Build automation system and improve understanding

2. Understanding and using machine elements

3. Network system communication control practice between PLC

4. Control of analog and digital signals

5. Practice of process control language based on PLC, PC, FPGA in mass production

6. Practice of Conveyor belt control by using HMI

7. Practice of each process monitoring by suing Gateway