PLC Function

1. Understanding and practicing timer and counter circuits.

2. Relay, sensor, switch, buzzer, DC motor, cylinder understanding and practice

3. Inductive, capacitive, photoelectric sensor understanding and practice

4. Pneumatic cylinder operation understanding and practice

5. HMI drawing practice (sequence, sensor, pneumatic, PLC application control)

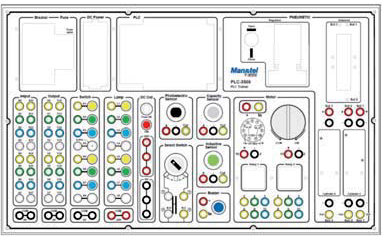

PLC Composition

PLC Specifications

| Product Name | Specification |

|---|---|

| Power | AC100~240V, input:16, output:16 points |

| PLC | 7 inch TFT LCD wide touch screen |

| Touch Screen | Set pressure: 0.05 to 0.85 MPa |

| Regulator | Rated output voltage: DC 24[V] |

| SMPS | ¥ 12 (Red, Yellow, Green, Blue) |

| Push Button Switch | Contact capacity: AC 220[V] |

| Selector Switch | Shape: 3 steps |

| Lamp | ¥ 12 (No, Green, Blue, White) |

| Buzzer | ¥ 16, 24[V] |

| Circuit Breaker (2 Pole) | Breaking current: 30[A] |

| Relay | Relay: DC24[V] |

| Solenoid Valve | Single, double |

| Cylinder | Single acting, double acting |

| DC Motor | Voltage: 24[V], Current: 7.7[A], Rotation speed: 3000[rpm] |

| Sensor Unit (Capacitive) | Voltage: 12[V]~24[V], Detection distance: 8[mm] ± 10[%] |

| Sensor Unit (Inductive) | Voltage: 10[V]~30[V], Detection distance: 100[mm] |

| AC Input | 220[V] |

PLC Training Contents

Chapter 1. PLC Overview

Chapter 2. PLC Architecture

Chapter 3. PLC Wiring and Commands

Chapter 4. FX-PLC Configuration

Chapter 5. GX-work2 operation

Chapter 6. PLC Basic Command Practice

Chapter 7. PLC Numerical Data Practice

Chapter 8. Application Command and Programming Practice |

Chapter 9. Application Command and Programming Practice ||

Chapter 10. Sequence Control Practice |

Chapter 11. Sequence Control Practice ||

Chapter 12. Sensor Control Practice

Chapter 13. Pneumatic Control Practice

Chapter 14. PLC Control Using Touch Screen

Chapter 15. HMI Drawing – Software Installation

Chapter 16. HMI Drawing – Basic Usage

Chapter 17. HMI Drawing – Download and Upload

Chapter 18. HMI Drawing – Sequence Control Practice

Chapter 19. HMI Drawing – Sensor Control Practice

Chapter 20. HMI Drawing – Pneumatic Control Practice

Chapter 21. HMI drawing – PLC application control practice

PLC Components

| Product Name | Quantity |

| PLC | 1 |

| touch screen | 1 |

| regulator | 1 |

| SMPS | 1 |

| push button switch | 1 |

| selector switch | 8 |

| Lamp | 8 |

| buzzer | 1 |

| Circuit breaker for 2-pole wiring | 1 |

| solenoid | 1 |

| valve cylinder | 2 |

| DC motor | 1 |

| fuse | 1 |

| capacitive sensor | 1 |

| inductive sensor | 1 |

| photoelectric sensor | 1 |

| banana cable | 1set |

| case | 1 |

| textbook | 1 |

PLC Product Size

| Attribute | Details |

|---|---|

| Product Size | 640(L) X 420(W) X 250(H) mm |

| Package Size | 670(L) X 500(W) X 270(H) mm |

| Weight | Bag weight: 18kg / Packing box: 20.5kg |