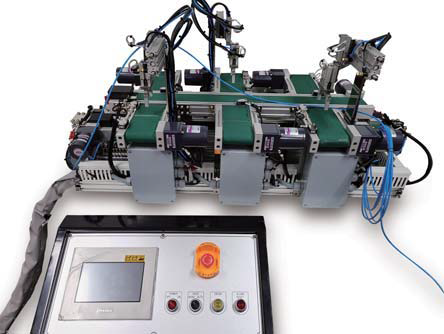

Features:

1. Practice of automated process inspection, transfer and sorting process

2. Structure suitable for transport and detection related to conveyors during automation process

3. Self manual operation function and automatic operation function by PLC connection

4. Conveyor operating principles and easy application experiment with various sensors

5. The finished product is returned through the double-layer conveyor belt structure, and it is automatically transferred to the product input process

6. Product classification process practice of gripper-type structure mainly used in industry

7. Conveyor Belt Monitoring System Practice Using Gateway

Functions:

1. Practice of conveyor belt control using HMI

2. Conveyor belt control practice using PLC CC-link

3. Practice of Gripper Control Using Electric Pneumatics

4. Servo motor forward and reverse circuit practice using inverter

5. Characteristic training by sensor type

6. Practice of Self hold, logic circuit, timer, counter circuit

7. Practice of Conveyor Belt Sequence Real Wiring Control